Radar solutions for challenging industrial applications

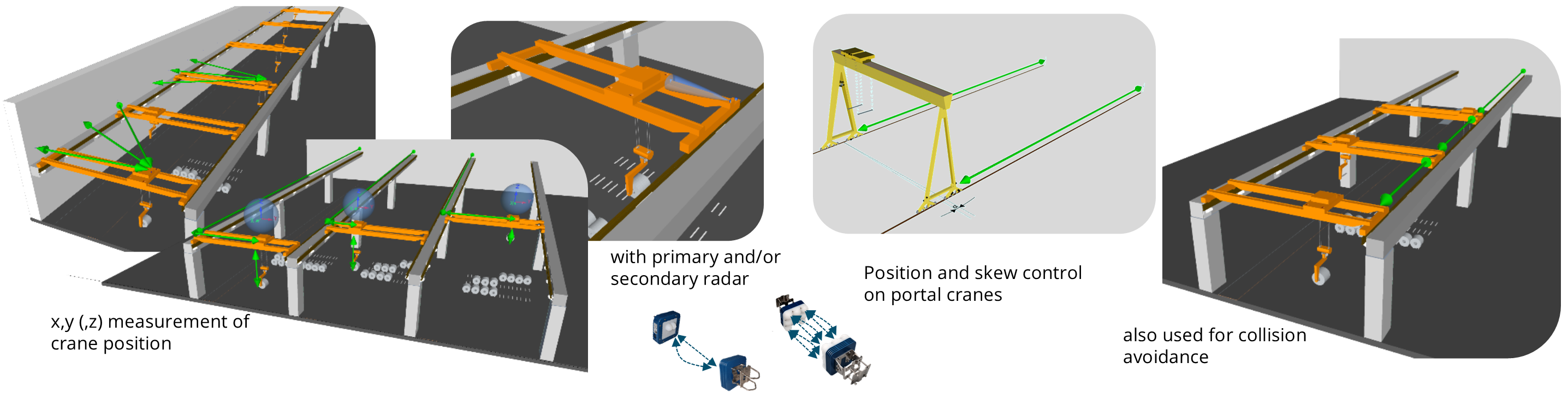

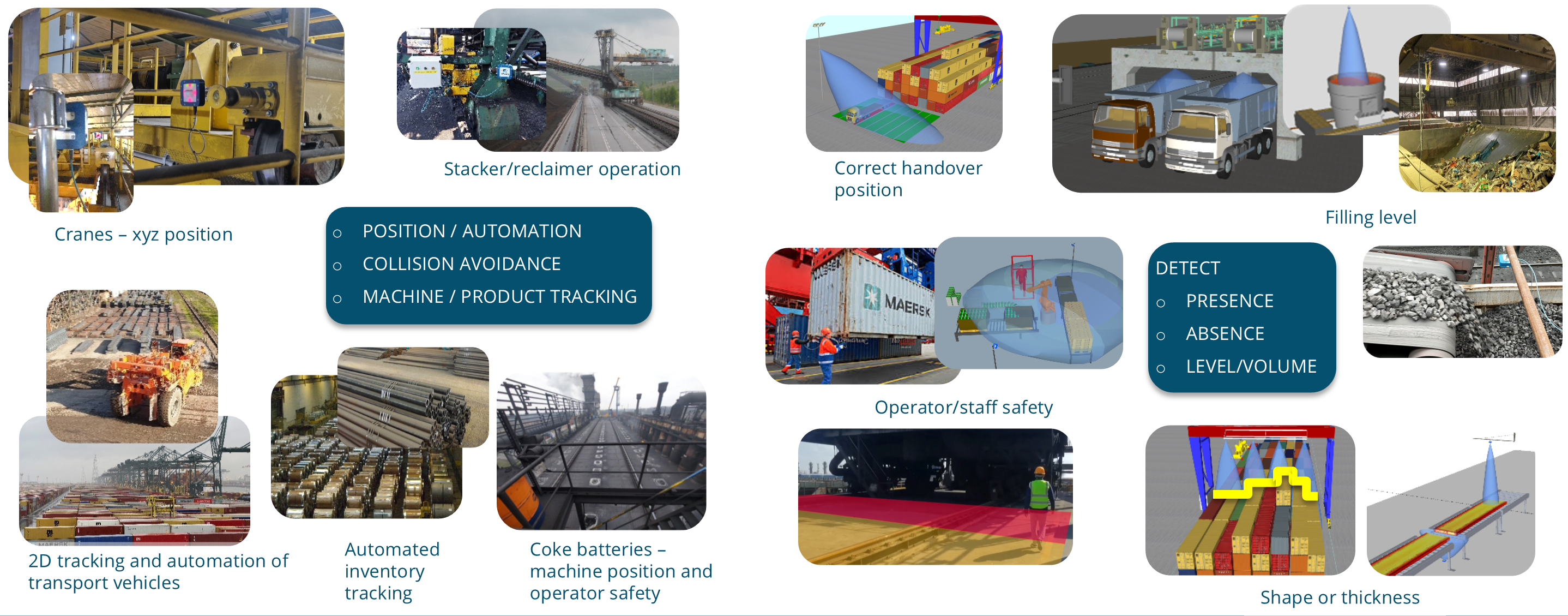

Maintenance-free position detection for all types of cranes, indoor and outdoor

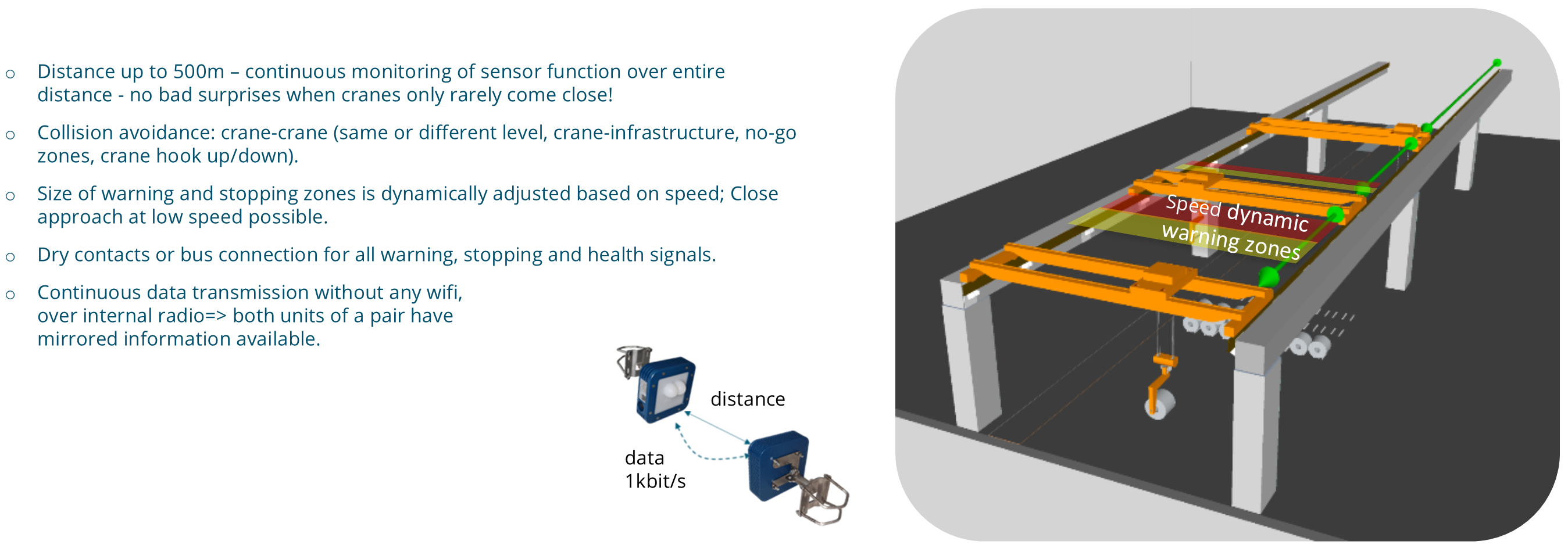

Dynamic avoidance of crane collisions

Collision avoidance for cranes and different layers

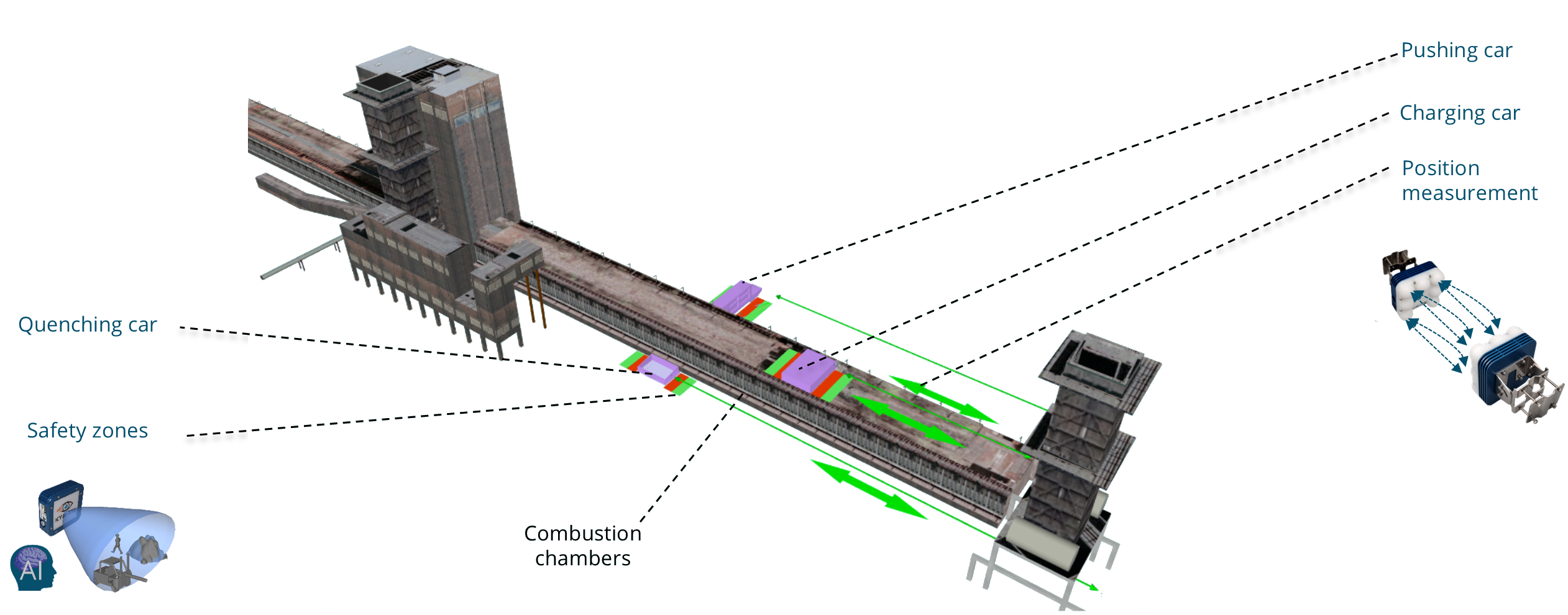

Radar for position detection of coke oven machines

Material tracking - scrap metal yard example

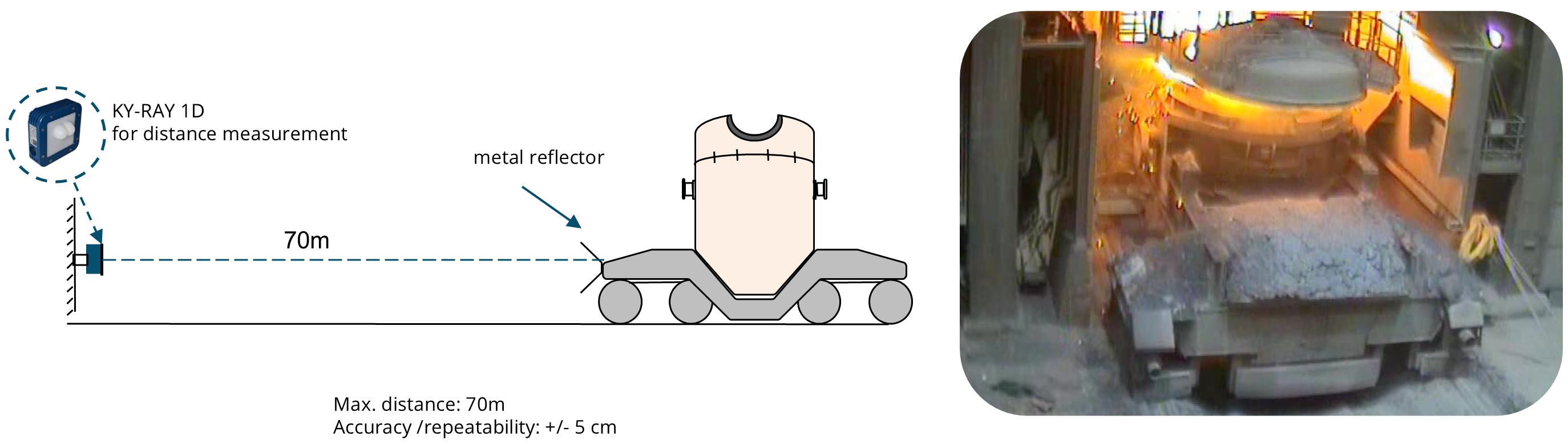

Radar ladle car position measurement without sensors in the hot zone

Radar in bulk material storage and processing

Application examples

Contact us!

Contact us!